A Cost That Is Incurred if Some Aspect of a Service Must Be Performed Again Is Called aN

Cost of Poor Quality (COPQ) is the cost associated with providing poor quality products or services to the client. In other words, it is the total financial losses incurred past the company due to performing incorrect things. For example, scrap, rework, repair, warranty failure.

Cost of Quality is a methodology used in the organization to measure out the amount of resources being used for the price of expert quality. In other words, it is the cost of achieving quality products or services.

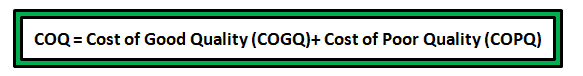

Cost of quality is the combination of price of proficient quality and price of poor quality.

Why Cost of Poor Quality (COPQ)

- COPQ tells how profit is affected past the quality

- Information technology speaks the linguistic communication of management

- Helps to prioritize improvement deportment

- Optimize the resources and also helps in identify wastes in the system

- Improves continuous improvement culture

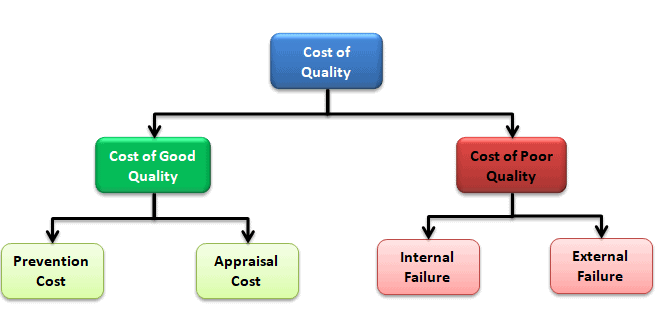

Categories of Price of Quality

Price of quality can exist divided into 4 categories: prevention price, appraisement cost, internal failure cost, and external failure price.

Preventive Cost– Preventive costs are the costs of the activities peculiarly designed to preclude poor quality of products or services. In other words, efforts are related to preventing failures.

- Quality planning

- Contract review

- Trainings

- Quality audits

- Supplier evaluation

- Market place inquiry

- Process adequacy studies

Appraisal costs – Appraisal costs are the costs incurred due to those activities which are performed to detect the poor quality of product or services. In other words, appraisal costs are related to testing, measuring, and auditing. The appraisal price focuses on the discovery of defects rather than the prevention of defects.

- Incoming goods inspection

- In-process inspection

- Supplier inspection

- Laboratory testing

- Last appurtenances inspection

- Calibration

Internal failure – Internal failure costs result from the identification of defects prior to commitment of the product or service to the customers. In add-on, these are the costs due to the failure of a product to achieve required quality standards.

- Rework

- Repair

- Internal scrap

- Re-testing

- Efforts spent on failure analysis

- Raw material rejection

- In-process rejection

External failure – External failure costs arise from the rejection of the product or services past the customers after commitment. In other words, these are the costs when a production or service fails to see the required quality standards and is detected afterwards it reaches the client.

- Warranty claims

- Client visits

- Penalties

- Replacements

- Investigations

- Loss of goodwill

When to use Price of Poor Quality (COPQ)

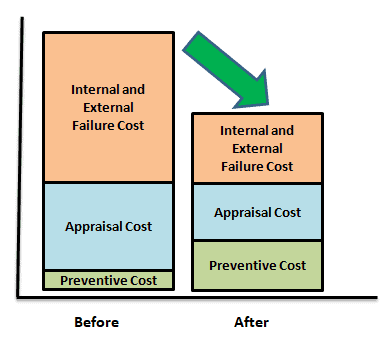

Organizations apply COPQ to empathize the opportunities to better the quality by reducing internal and external failure costs. Basically, by increasing the expenditure on prevention.

Steps in implementing Toll of Poor Quality (COPQ)

- Define the organization quality goals and objectives

- Estimate the electric current capabilities of machines, systems, and processes

- Collect data for prevention toll, appraisement cost, internal failure cost and external failure cost

- Validate the quality cost data with finance

- Pareto the quality costs and prioritize the actions

- Implement the corrective actions such every bit automate the quality audits, streamline the inspection process, implement Poka-Yoke etc.,

- Compare the quality costs before and after process comeback (as shown below)

- Finally, present the quality cost improvements to top management.

Example of Price of Poor Quality (COPQ)

Quality assurance is everything for an organization. Incorporating 6 Sigma and other Lean tools, this allows companies to decrease waste (Raw materials, Logistics costs, and unnecessary man hrs) which increases their lesser line.

Let's say you lot are running a DMAIC project. In the define phase, you lot desire to quantify the cost of poor quality. You start by defining what a defect is, then measuring how many defects per one thousand thousand opportunities your process has. (You would utilize this same material to create your baseline sigma in the measure out stage, next.)

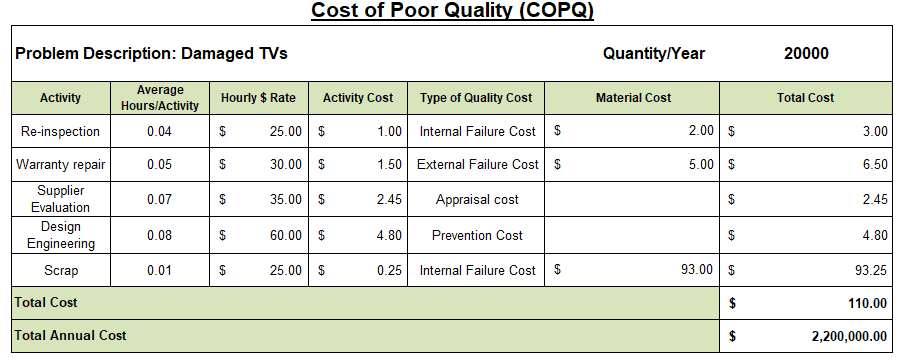

Case: Imagine producing TVs and for every 1M produced 2% were damaged… That'due south twenty,000 TVs. If those amercement were not salvageable, and it cost $100 to produce each unit of measurement, then it cost your company 20k *$100 = $2 One thousand thousand

Just that's not all. How many people would you work on re-inspection, warranty repair, supplier evaluation etc.? Here yous go for the breakup of the costs. Below are the dissever-up of various costs (Just equally an example).

Total material cost is $100 unit of measurement and an additional $x per unit spent on quality costs. At 20k units, that is $200k. The total price to the company would be $2.2 Million!

Cost of Poor Quality Template

Why Pursue a Six Sigma Level of Quality / Excellence?

Let's use the aforementioned instance. At a 6 Sigma level you lot would only produce three.4 defects per million opportunities. In the previous example the process was making xx,000 defects per one thousand thousand. Moving to a six sigma level of quality would hateful 19,996.6 less defects per 1000000 units fabricated! That's a savings of $two.2M – (3.four * $110) = $2.2M – $374 … so, nearly $ii.2 One thousand thousand!

Avoid Errors

The best in whatever field figured out how to avoid errors very early on. We should, also, if nosotros desire to engineer a nifty process.

For instance, Simon Ramo notes that amid the very best lawn tennis players, to win y'all need expert winning shots; to be a good boilerplate thespian, you demand to just lower your failure rate. In practiced tennis, lxxx% of the points are won, while in amateur tennis, fourscore% are lost. The same is true for wrestling, chess, and investing: beginners should focus on avoiding mistakes, experts on making great moves. – Erik Falkenstein, Author The Missing Take a chance Premium

"The near important thing to practice if you notice yourself in a hole is to end digging."

Warren Buffett

Disadvantages of Price of Poor Quality (COPQ)

- Financial loss

- Schedule filibuster

- Need more controls and checks

- Unnecessary spent on resources

- Leads to associates de-motivation

- Reputation at stake

- Competitors accept reward

Cost of Poor Quality (COPQ) Videos

Ironically, this video has poor sound quality, but the content is good.

Videos on the Economical Considerations of Quality

Cost of Poor Quality (COPQ) Books

Quality is Gratis

Like every other homo domain, we need to identify what the problem is before nosotros can fix it. And that doesn't always happen in business concern.

"The beginning erroneous assumption is that quality means goodness, or luxury, so shininess, or weight. Nosotros must define quality as conformance to requirements if we are to manage it. The second erroneous assumption is that quality is an intangible and therefore not measurable. In fact, quality is precisely measurable past the oldest and most respected of measurements – common cold difficult cash. Information technology is much less expensive to prevent errors than to rework, flake or service them." – Quality is Free

The book has a quality improvement program that can exist installed in any service or manufacturing company.

Business @ Speed of Thought

I list this here because Bill Gates' Business @ the Speed of Thought is influenced by Crosby'due south Quality is Costless work. It may resonate a lilliputian better with modern audiences as the example studies are newer – despite existence 16 years old in 2015. Simply you can encounter the bones concepts of Quality is Free represented hither.

- In that location is no reason for having errors or defects in whatsoever production or service.

- Businesses are tedious to change because we reject newness.

- How you come across to others should not exist left to take chances. Quality products and services is something you can control.

- It is much less expensive to forestall errors than to have rework.

Likewise Encounter

Hidden vs Visible Costs

Vi Sigma Black Belt Certification Cost of Poor Quality Questions:

Question: Which of the following all-time describes internal failure costs? (Taken from ASQ sample Blackness Belt examination.)

(A) The economic costs associated with a catastrophic failure of an internal subsystem.

(B) The unavoidable quality organization costs associated with the production of any production or service.

(C) The opposite of external failure costs.

(D) The costs resulting from a nonconformance detected earlier a product or service is provided.

Answer:

Question: Which of the post-obit will have the virtually influence on consumers' perception of quality?

(A) Industry standards

(B) Company financial performance

(C) Audit results

(D) Service and repair policies

Answer:

Source: https://sixsigmastudyguide.com/cost-of-poor-quality/

Post a Comment for "A Cost That Is Incurred if Some Aspect of a Service Must Be Performed Again Is Called aN"